Module 13 - CNC course & training

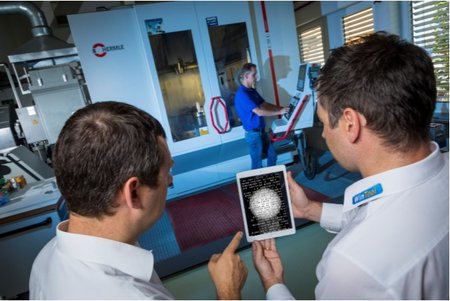

Digitization in the machining environment

In order for cutting tools to be efficient, not only well-founded technological knowledge is required, but also a solid understanding of the system. The machining process is increasingly supported and shaped by software. Starting with order planning through the programming process in CAM systems to the generation of tool and setup lists with connection to procurement and storage, there are a number of now digital work steps. The reason is simple - efficiency.

In order to maintain an overview and to be able to create a tailor-made concept for your own company, this qualification module provides a comprehensive introduction to the following subject areas:

• Introduction to software systems in the field of machining

• Master data quality as a basic requirement for

Digitization and automation approaches

• Normalization, classification and standardization -

Recommendations for action for the structure of tool data

• Workflow-controlled creation of tool master data

Master the process

• Presentation of a TCM analysis to determine potential

through increased digitization of processes

• Importance and efficiency of tool management

systems at shop floor level

• Live demo of a modern, integrated system landscape

- from order to chip

- Benefit consideration

• Trends, research & development on tool data,

Wear detection and machine monitoring

Your benefit:

You create a valuable foundation for yourself.

Duration: 8 hours

Number of participants

at least 5, max. 15 participants

Target group:

- Machine operators CNC machines

- Machine skilled workers, adjusters CNC machines

- AV employees, CNC programmers

- tool purchase

- Employees in the tool presetting and management

- Metal cutting apprentices