Master data management

In terms of digitization, it is important to reinterpret many technological design options. The linking of individual areas and departments forms a strategic asset for process and service innovation, advances success and increases competitiveness.

The existence of tool master data for all systems in a company - from purchasing to planning and programming to the workshop or CNC production - is the basis for efficient and value-added processes

Good master data, what does that mean for you?

Master data is often created in various departments and programs and saved on different data storage devices. This leads to the master data are not being uniformly structured and thus a networking of the systems is made more difficult. The consequence of this is "unproductive processes".

Our solution - the tooltracer

This means that tool master data from different sources can be managed uniformly and absolutely flawlessly (this is important!) And used from there in the machining process and in the core systems.

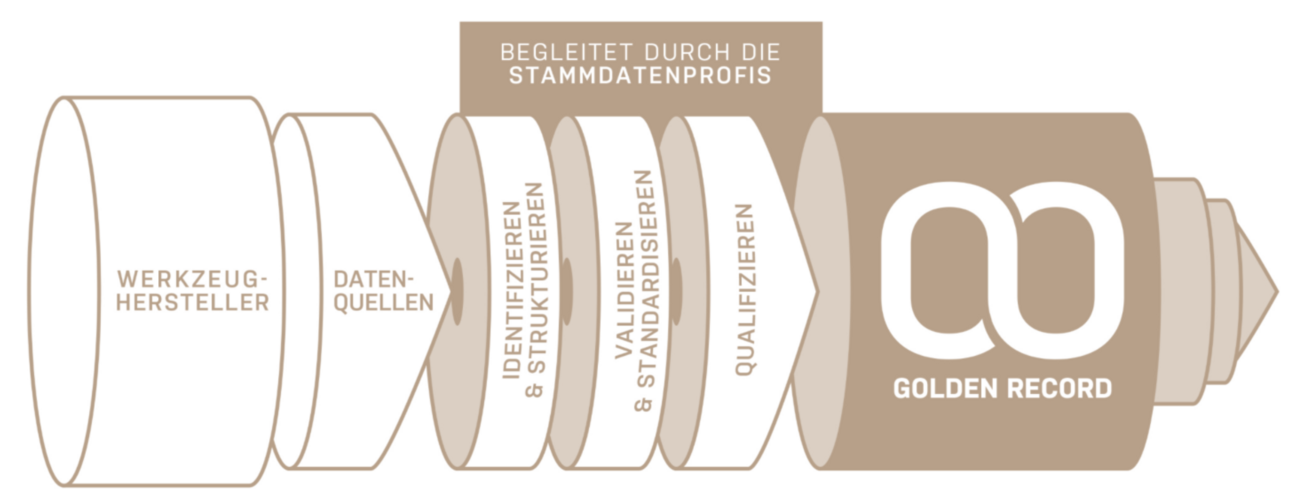

Through a guided process, companies create their "golden record", the uniform and error-free tool data set - consisting of geometric, commercial and application-relevant data in all systems. As a basis for programming, simulation, procurement and administration in the sense of networked production.

Visit our new webseite!

www.tooltracer.com

Do you love your Masterdata?

Master data plays a central role in the success of companies.

If you want to be successful in the marketplace of the future, you should attach importance to this topic. The TCM white paper "Do you love your master data?" is intended as a guide to taking a first step towards quality master data.

01 WHAT ON EARTH IS DIGITALIZATION?

02 TODAY, MASTER DATA IS A BURDENSOME OBLIGATION.

03 A PICTURE SAYS MORE THAN A TOHUSAND WORDS.

04 100 PERCENT DATA QUALITY IS ONLY JUST GOOD ENOUGH.

05 DIGITALIZATION REQUIRES LEADERSHIP.